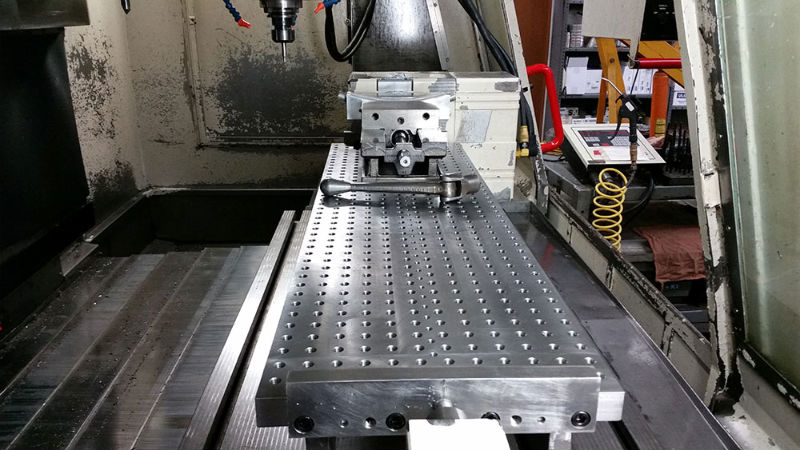

Computer Numerical Control machining or CNC machining is the process by which certain types of equipment (such as grinders and mills) are controlled. CNC operated machines with unique computers that operate in G-code. This code is written by an engineer to control every single aspect of the device from the processing speed to the loading and unloading capabilities.

Several steps must be taken in the development and testing of a CNC machine before it can be used by a cnc machining company.

Creating a CNC Machine

Before such machine can be built, the engineering company designing the piece of equipment creates a CAD drawing (2D or 3D detailed and computerized drawing) of the item. Then, the necessary G-code information is written and incorporated into the prototype.

Testing

Once the code is written and the machine built, an extensive series of tests must be run to ensure that every aspect is operating and understanding the code properly. Each direction the machine should follow is tested. If everything operates properly, the machine is ready to be used by the CNC machining company.

Advantages

CNC machining offers many advantages. First of all, it offers a level of precision that just cannot be attained manually. This allows for even the most complicated shapes to be manufactured with little trouble and complete accuracy. It’s also more efficient. With the ability to set production rates, the machine can operate continually by reading the applicable code while manual machining requires additional labor and, therefore, takes longer for less accurate results.

Repetitive orders are best for CNC machines as they can repeat the same action over and over with the same level of precision and accuracy. CNC machines also have the ability to work with multiple accessories. Therefore, a CNC machining company can use one machine for several tasks.

Alternates

There are no equal alternates to CNC machining. However, manual machining is still used is some circumstances. Manual machining is a slower process because it requires a “resetting” each time while CNC machining can continue a task repeatedly. Manual machining is also less accurate as it relies on a human operator setting rather than the G-code for exact measurements.