Testing arresters is an important part of power factor tests that is often overlooked. Other times, it may be policy to not do any testing at all. Beyond identifying surge arresters that need replacing, testing helps to identify when a reduced voltage is producing a resistive current, a plus/minus sparkover operating voltage or in identifying defects in arresters being made with newer materials. An arrester in need of replacement can be dangerous, which is why having the proper arrester tester and power supply for an arrester tester is important.

What do Surge Arresters Do?

Transient overvoltages can damage an apparatus. With the help of a low-impedance path to ground a current from overvoltage or a lightning strike, arresters protect an apparatus from frying. It does this by quickly identifying the excess voltage and finds a path to ground to and limit and safely control the voltage unload. It’s pretty incredible that the arrester is able to provide a point for the overvoltage to be redirected to ground while still keeping the appropriate current running at a normal rate. In this way, an arrester is like a gatekeeper. Strange as it sounds, arresters have been in use, in one form or another, since the early 1900’s.

Types Of Arresters

There are three types of arresters: Silicon-Carbide, MOV and Polymer/Porcelain Arresters; the most popular of the three being the Metal-Oxide Varistor (MOV). The MOV has been in service for close to 40 years. It is preferred over Silicon-Carbide Arresters because it is gapless, which reduces the high heat generated by arcing discharges and has two voltage ratings: duty-cycle rating and maximum continuous operating voltage (SCA’s only have one, duty-cycle rating). Polymer arresters are being installed more and more over porcelain arresters. One reason for this could be that porcelain arresters can explode after it is subject to a second fault current.

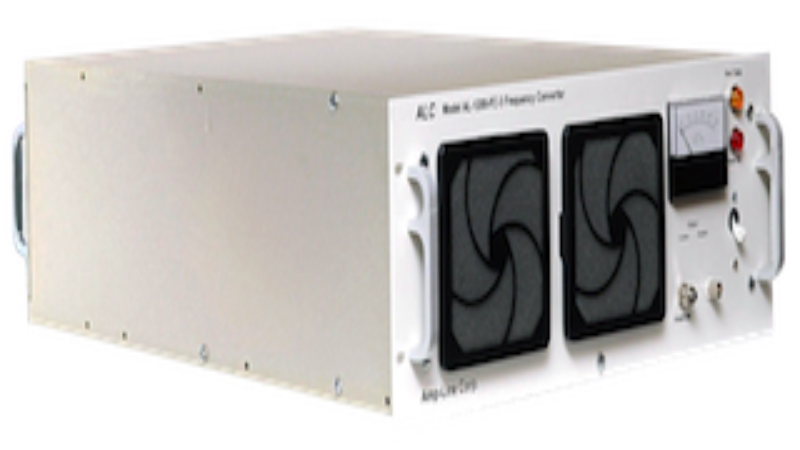

Doing The Testing

An arrester tester can identify faulty valve insulation, which can lead to moisture inside a device. In order to get an accurate reading, you must measure the whole current, resistance current and its harmonics. When testing on a metal-oxide arrester, a residual amount of static charge is left, so it is important to install a temporary ground line as a safety precaution. To determine if a SCA needs replacement, it is best to use the watts-loss test and compare it to another arrester. When testing arresters it’s important to take every safety precaution and use proper tools such as a certified power supply for an arrester tester and a trusted arrester tester. Clicke here for more info.